❖ Soil Tests

At Ramssko laboratory, we provide comprehensive services for soil testing and implementation of borehole works, using the latest tools and advanced technologies, and under the supervision of a team of experts with high experience in this field. We aim to provide accurate and reliable data that meet the needs of any engineering project with the highest levels of quality.

These tests include:

- Field Tests: Including Standard Penetration Test (SPT), Cone Penetration Test (CPT), Vane Shear Test, Soil Permeability Determination, Standard Compaction Test (Sand Cone), Plate Load Test, and Monitoring Well Test

- Laboratory Tests: Including soil classification, moisture content, Atterberg limits, grain size analysis, free swell, unit weight, relative density, specific gravity, direct shear test, consolidation test, float test, and chemical analyses.

❖ Compaction Test

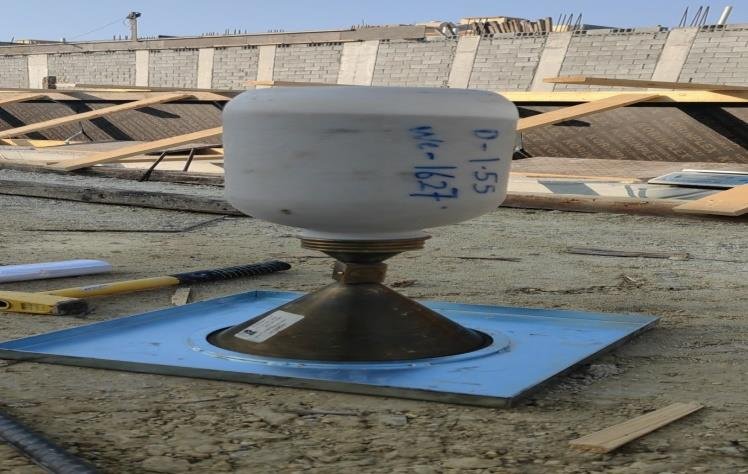

❖ Plate Load Test

The plate load test is used to estimate the bearing capacity of homogeneous soil and the amount of settlement for soils from which it is difficult to extract intact samples, such as sand and cracked clay, as well as to test the effectiveness of compaction of gravelly soils.

- A square loading plate with a side length of 300 mm or a circular plate with a diameter of 300 mm and a thickness of 25 mm is used. Sometimes, a square loading plate with dimensions of 706 mm is used.

- The plate is equipped with settlement measuring devices with an accuracy of 0.02 mm.

- The test requires a water level, settlement measuring tools, and a stopwatch.

- The results show the type of loading device used and the settlement details with precision.

❖ Concrete Tests

The Ramssko laboratory provides comprehensive services in concrete quality testing and supervision of concrete pours, using the latest technologies to ensure compliance with required specifications and standards.

These tests include :

A - Determining and monitoring temperature: The temperature of the concrete is measured and monitored during pouring to ensure it meets the required standards and specifications.

B - Determining the concrete slump value ( Slump Test ) : This test is used to determine the concrete's flowability and its ability to be poured without cracking.

C - Determining the air voids ratio in the fresh concrete sample ( Air Voids ) : The percentage of voids in the concrete is measured to verify its efficiency and durability.

D - Taking cubic and cylindrical concrete samples on-site, preserving, and processing them according to engineering standards, which helps in evaluating their quality and conformity to standards.

E - Concrete elasticity test: This test is performed to determine the concrete's ability to withstand deformations and vibrations during its service life.

F - Concrete shrinkage test: Used to determine the concrete's capacity for endurance and stability which helps in evaluating its long-term performance.

❖ Construction Materials Tests

The Ramssko laboratory provides high-performance and quality services in construction materials testing, to ensure the quality and conformity of the materials used in construction to the required specifications and standards. The laboratory's services include tests for the following construction materials:

- Steel: Tests to determine the properties of the steel used in building structures, such as tensile strength, bending, and welding.

- Cement: Tests to evaluate the quality of the cement used in concrete, such as compressive strength tests and chemical analysis.

- Stone: Evaluation of the properties of the stone used in construction, such as durability and bearing capacity.

- Sand: Tests to determine the void ratio and compressive strength of the sand used in concrete and other construction materials.

❖ Asphalt Tests

The Ramssko laboratory provides comprehensive services in performing all field and laboratory tests for asphalt, as well as preparing cement mixes in the laboratory and conducting the necessary tests (temperature, thickness, and asphalt compaction strength).

❖ Structural Evaluation of Existing Buildings

The structural evaluation process begins with a general inspection of the facility, followed by a comprehensive structural analysis, including:

- Visual Inspection and Examination: Includes inspection of all parts and areas of the buildings.

- Providing the required test plan: Ensures compliance with the design principles, codes, and general specifications.

- Conducting the Tests: Carried out using the approved methods and techniques in the relevant engineering codes, and include:

- Non-destructive tests: such as Schmidt hammer and ultrasonic waves.

- Semi-destructive test: such as core testing.

- Destructive test: such as load testing according to the code.

- Chemical tests.

- Structural Evaluation Reports

Separate reports are provided, including:

- The safety condition of the facilities and elements under test.

- A report on the structural safety of the buildings, containing all information and data.

- Proposed repair and treatment methods.

- A sequential system of the treatment process and repair methods for each structural element with a coded numbering and diagram.

- Approved reports and final recommendations.